Our Capabilities

We offer a comprehensive range of metal fabrication and machining services to meet your most demanding requirements. Our state-of-the-art equipment and skilled technicians ensure precision results for every project.

Laser Cutting & Blanking

Fast, precise cutting of complex geometries in sheet metal materials.

- Mazak Super Turbo 510 4kW

- Aluminum and stainless steel

- Prototypes and production runs

Machining

Precision material removal for creating complex features and tight tolerances.

- Trak TMC 10 CNC mill

- Vertical & horizontal knee mills

- Turning capabilities

Metal Forming

Transform flat sheet metal into three-dimensional components with precise bends.

- 100 ton Accurpress 12ft capacity

- 35ton 6ft press brake

- Consistent, repeatable results

Turret Punching

Cost-effective fabrication for holes and cutouts in sheet metal components.

- Amada Vela 35-ton turret punch

- Efficient production of repeated patterns

- Holes, knockouts, and standard features

Robotic Welding

Consistent, high-quality welds for production runs with precise repeatability.

- Hirebotics collaborative robot

- Miller Invision 350MPA power source

- Programmable for consistent results across production runs

- Ideal for mid to high volume manufacturing

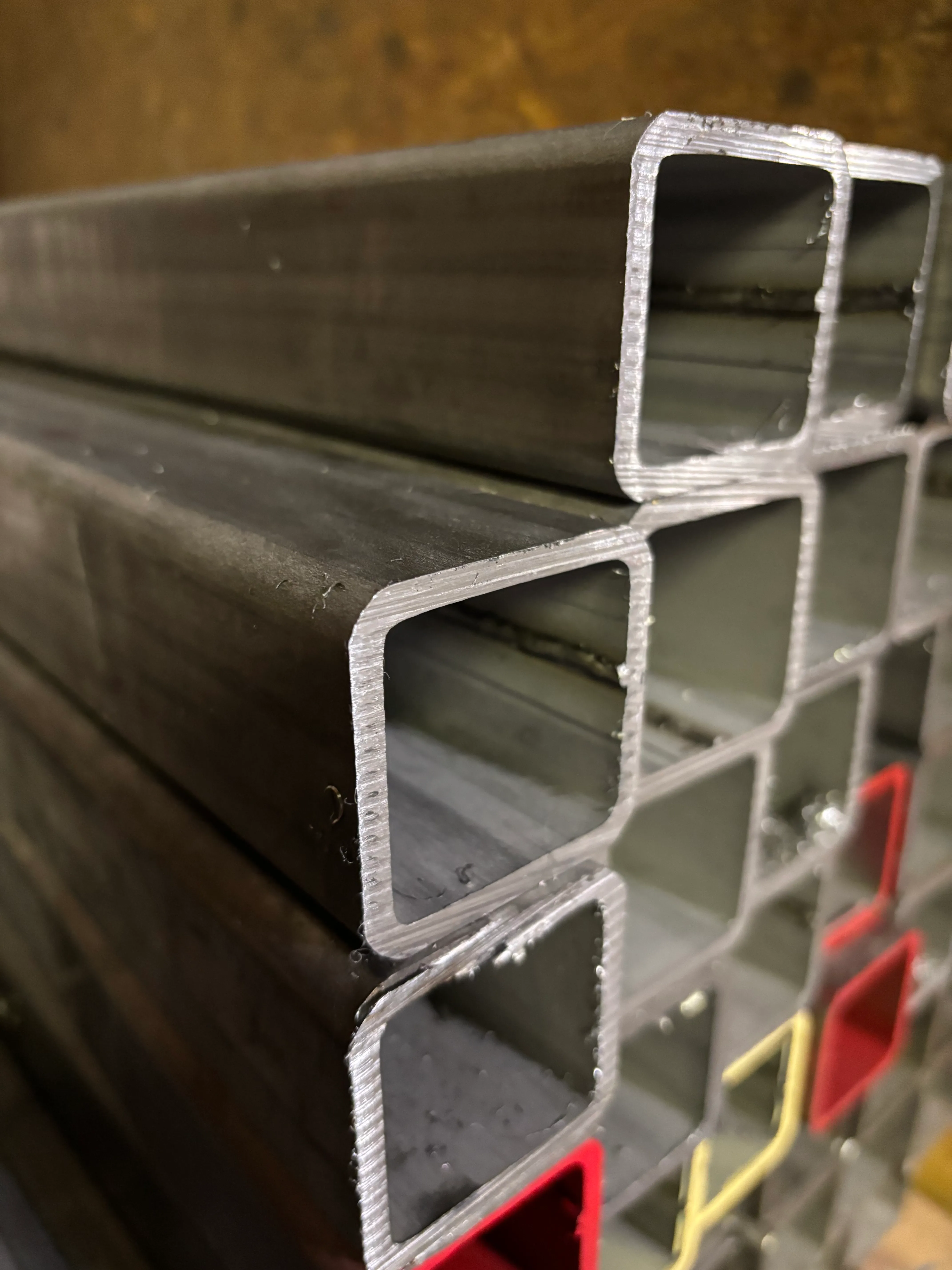

Saw Cutting

Accurate cutting of metal bar stock, tubing, and structural shapes.

- Precision cuts for further processing

- Handles round, square, and rectangular tubing

- Efficient processing of production quantities

TIG & MIG Welding

High-quality manual welding for aluminum, stainless steel, and carbon steel.

- Miller Syncrowave 300, Dynasty 200

- Lincoln PowerMIG 250

- Aluminum, stainless and carbon steel

- Consistent, high-quality welds

Resistance & Stud Welding

Specialized joining methods for specific applications without traditional fusion welding.

- Spot welding for quick, clean joining of sheet metal

- Stud welding for attaching fasteners directly to metal surfaces

- Ideal for applications requiring minimal heat affected zones

Metal Finishing

Surface treatments that enhance appearance and performance of metal components.

- Deburring and edge finishing

- Passivation of stainless steel components

- Surface preparation for painting or powder coating

Product Assembly

Complete your manufacturing process with partial or complete product assembly.

- Assembly of fabricated components into finished products

- Hardware installation and fastening

- Quality verification of assembled units

Laser Cut. Formed. Welded. Delivered.

We specialize in repeatable, high-quality metal components for production-focused teams. Reach out today to get started or request a quote.